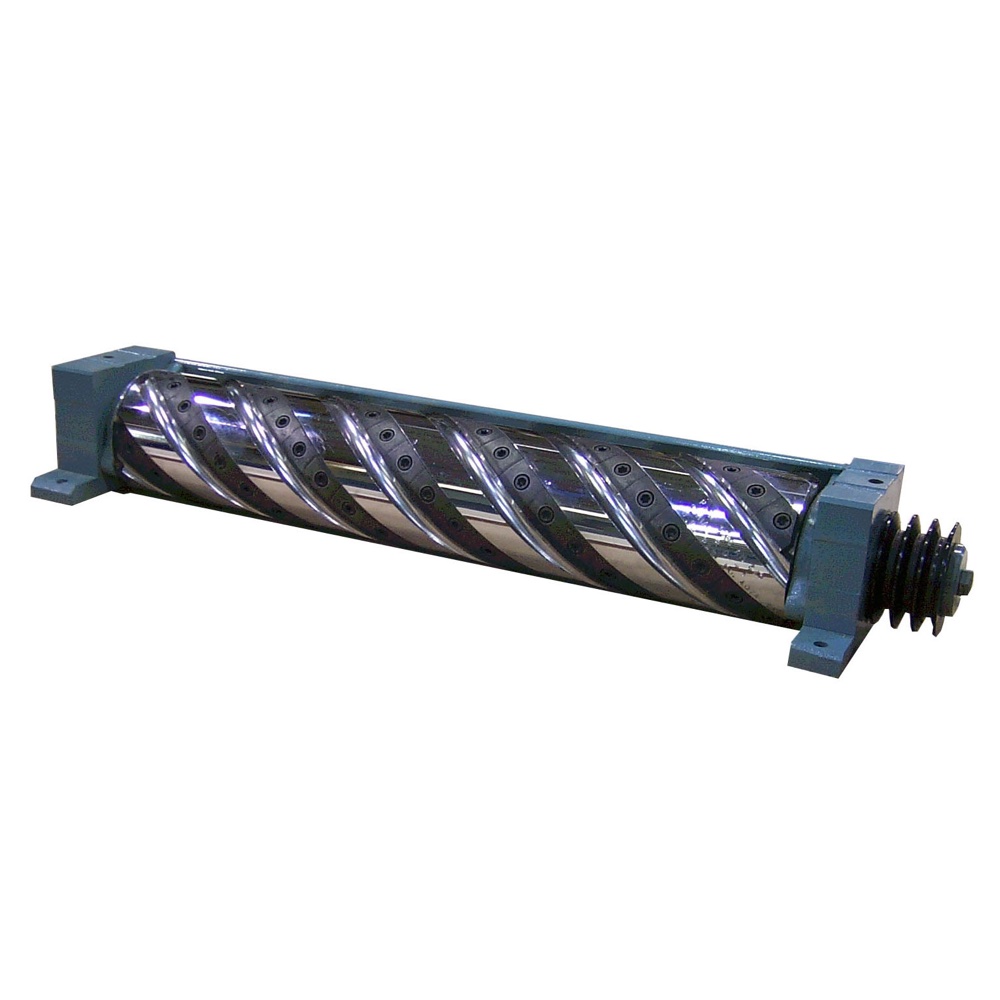

Newman Helical Carbide Cutterhead

The Newman Helical Carbide Cutterhead provides significant improvements over conventional cutterheads in terms of noise, cost, and performance. The Challenger Award winning cutterhead has become the industry standard. Replaceable carbide tipped cutters fit precisely into the helical slot to form a continuous helical cutting edge providing the most technologically advanced cutting action available. Newman Helical Carbide Cutterheads are being used extensively in the woodworking and plastics industries throughout the world with applications including finish planers, roughing planers and high- speed planer-matchers.

Description

The Newman Helical Carbide Cutterhead provides significant improvements over conventional cutterheads in terms of noise, cost, and performance. The Challenger Award winning cutterhead has become the industry standard. Replaceable carbide tipped cutters fit precisely into the helical slot to form a continuous helical cutting edge providing the most technologically advanced cutting action available. Newman Helical Carbide Cutterheads are being used extensively in the woodworking and plastics industries throughout the world with applications including finish planers, roughing planers and high- speed planer-matchers.

NOISE REDUCTION:

Due to their helical geometry, Newman Helical Carbide Cutterheads are continuously engaged with the work piece, unlike conventional straight knife cutterheads, which dramatically reduce work piece vibration and thus the noise normally associated with planing. The helical design also reduces aerodynamic noise (idling noise) by eliminating air compression. Noise reductions are typically 15-20 dBA as compared to conventional straight knife planing, meeting OSHA requirements in most cases.

LOWER OPERATING COSTS:

The Newman Helical Carbide Cutterhead is also more economical to operate. When considering initial cost, knife replacement cost, maintenance cost, and downtime cost, the helical carbide cutterhead has been proven to be considerably more economical to operate than conventional high-speed steel cutterheads.

HIGHER PERFORMANCE:

The use of carbide as opposed to high speed steel, when combined with helical cutting action, provides unsurpassed performance: long edge life (many times that of high-speed steel), ability to surface difficult materials (cross grain cutting, particleboards, etc.), easy replacement of inserts, and in-machine grinding and jointing. Consequently, the long intervals between cutterhead maintenance result in substantially less downtime and therefore less total maintenance time.

You must be logged in to post a review.

Reviews

There are no reviews yet.