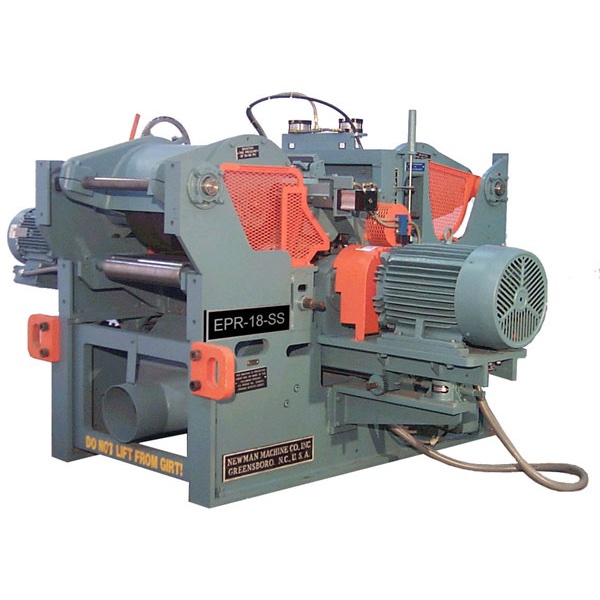

EPR-SS Short Stock Double Planer (18″, 24″, or 30″)

The Newman Short Stock Series double roughing planers are designed to surface rough lumber in both short and long lengths. Planers in this series have the additional capability of surfacing lumber almost one-foot shorter than roughing planers previously available in this class. The

In keeping with Newman's tradition of innovation the

Description

The Newman Short Stock Series double roughing planers are designed to surface rough lumber in both short and long lengths. Planers in this series have the additional capability of surfacing lumber almost one-foot shorter than roughing planers previously available in this class. The

In keeping with Newman’s tradition of innovation the

Maximum Feed Opening:

- EPR-18SS: 18″ x 6″ (450 mm x 150 mm)

- EPR-24SS: 24″ x 6″ (610 mm x 150 mm)

- EPR-30SS: 30″ x 6″ (762 mm x 150 mm)

Critical Dimensions:

- Minimum Stock Thickness – 3/8″ (9mm)

- Minimum Stock Length – 42″ (106.7cm)

- Feed Roll Center Distance – 40″ (101.6cm)

Feed Speeds:

- Minimum Feed Speed – 80 FPM (24 mpm)

- Maximum Feed Speed – 400 FPM (122 mpm)

Cutterheads:

- Standard – 7″ Cutting Circle, 8-Knife Pocket Type High Speed Steel

- Optional – 7″ Cutting Circle, 8-knife Helical Carbide

- Optional – 7″ Cutting Circle, 10-knife Helical Carbide

Cutterhead Motors:

- EPR-18SS – Top: 40 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled. Bottom: 25 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled

- EPR-24SS – Top: 60 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled. Bottom: 50 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled

- EPR-30SS – Top: 75 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled. Bottom: 50 HP, 3600 RPM @ 60 Hz, TEFC Premium Efficiency Coupled

Feed System:

- Top – Two 16″ pneumatic rolls with 1″ independent yield, each powered by 15 HP (10 HP on EPR-18) SEW Eurodrive helical gear motor with AC Variable Frequency Drive

- Bottom – Three 4″ diameter steel infeed rolls and two 4″ diameter steel outfeed rolls

Top Head Chipbreaker:

- Independently yielding 3″ wide sections. ½” yield per section

- Air operated quick release is standard

Feed Roll Positioning:

- Infeed Top Roll is tensioned by a 4″ air cylinder with in-line check valves to maintain set position. The air cylinder is also used for quick open and reset

- Outfeed Top Roll is positioned by a 4″ bore cylinder with in-line check valves to maintain set position

Thickness Setting System:

- The top cutterhead is equipped with a powered hoist and absolute encoder feedback. The system is controlled by an Allen Bradley PLC. The operator enters the desired finished thickness of lumber and presses the “Set Heads” button on the feeder console. The head will then unlock and move to the setpoint. The system is equipped with a calibration feature for use after jointing the cutterheads.

Optional Equipment:

- Automatic Cut Control TM

- Anti-lap device – watch video clip

- Pinch rolls

- Anti-kickback fingers

- Digital thickness positioning of top head

- Helical Carbide Cutterheads

- Remote console to extend planer controls to operator’s position

- Top head power hoist

- Air operated pressure bar release

- Hydraulic drive

You must be logged in to post a review.

Reviews

There are no reviews yet.