S-382-E Double Roughing Planer

Video for S-382-E Double Roughing Planer

Video for S-382-E Double Roughing Planer – Video 2

Video for S-382-E Double Roughing Planer – Video 3

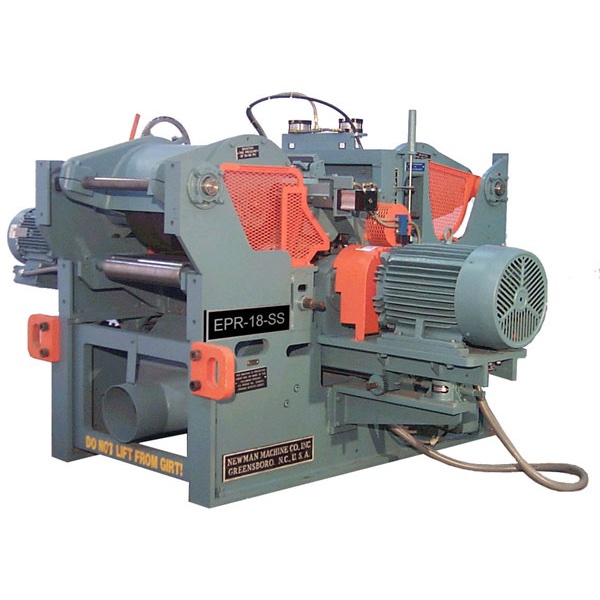

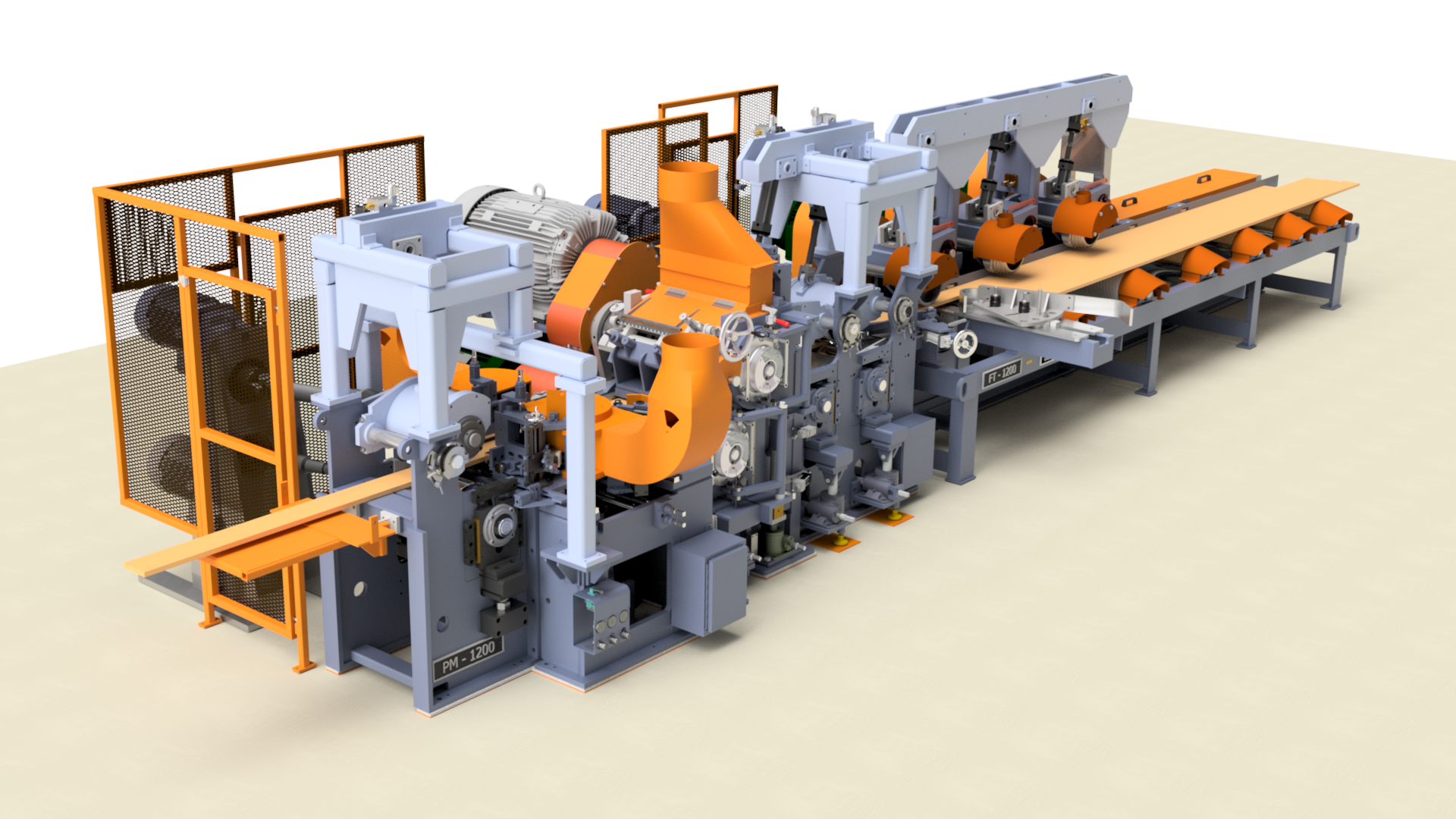

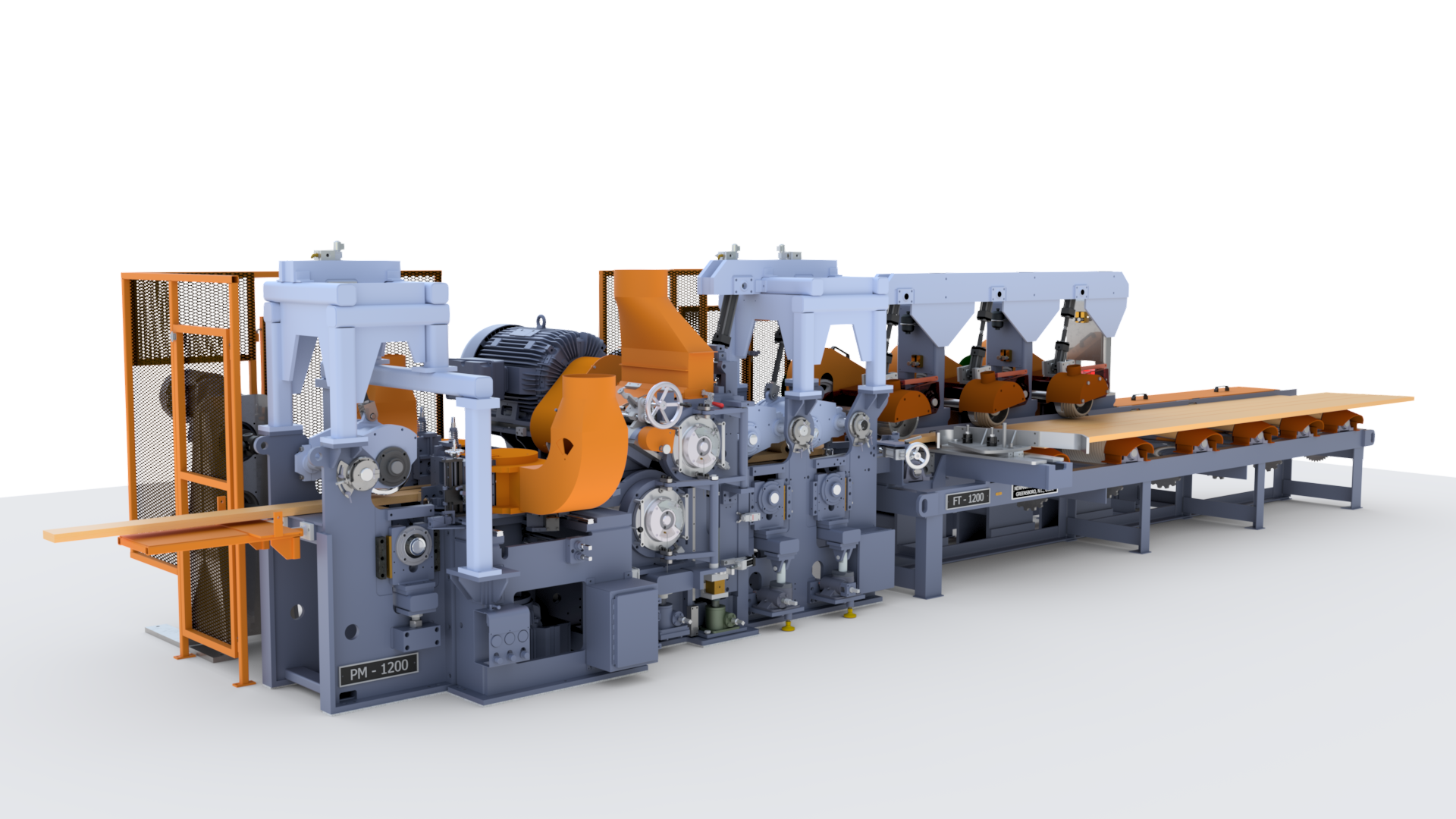

The Newman S-382-E is designed to take random width rough sawn lumber and calibrate it to target thickness. It has a 30″ (762 mm) width capacity and now comes standard with electric feed drive! The S-382-E will process lumber at speeds of from 80 to 300 FPM (25 to 92 mpm) and may be equipped with either the Newman Helical Carbide Cutterheads or the standard high speed steel cutterheads.

Two 15 HP Sew-Eurodrive gearmotors are mounted directly onto the feed shafts. The feed shafts have changed from the hex shaft configuration to the new interconnected hub design. Two AC variable frequency inverters allow for precision infeed and outfeed roll synchronization, aiding in extended tire life.

Description

Video for S-382-E Double Roughing Planer

Video for S-382-E Double Roughing Planer – Video 2

Video for S-382-E Double Roughing Planer – Video 3

The Newman S-382-E is designed to take random width rough sawn lumber and calibrate it to target thickness. It has a 30″ (762 mm) width capacity and now comes standard with electric feed drive! The S-382-E will process lumber at speeds of from 80 to 300 FPM (25 to 92 mpm) and may be equipped with either the Newman Helical Carbide Cutterheads or the standard high speed steel cutterheads.

Two 15 HP Sew-Eurodrive gearmotors are mounted directly onto the feed shafts. The feed shafts have changed from the hex shaft configuration to the new interconnected hub design. Two AC variable frequency inverters allow for precision infeed and outfeed roll synchronization, aiding in extended tire life.

To reduce damage to cupped or misshapen boards the feed system utilizes pneumatic rubber tires, virtually eliminating roller split while providing positive high torque feed. To increase yield the S-382-E can be equipped with our patented Automatic Cut Control™ (A.C.C.) which is designed to prevent boards from being planed to less than target thickness.

Maintenance saving options such as in-machine knife grinding and computer setworks are also available. Utilizing soft feed, exceptional knife work, along with controlled thickness dimensioning, lumber yields will increase, the product will improve, and production will grow.

Capacities:

- Maximum Feed Opening: 30″ x 6″

- Minimum Stock Thickness: 3/8″

- Minimum Stock Length: 51″ (48″ when butted)

Feed Speed:

- Minimum Feed Speed: 80 fpm

- Maximum Feed Speed: 300 fpm

Standard Cutterheads and Optional Cutterheads:

- Standard: 6-knife, high speed steel 7″cutting circle

- Optional: Helical Carbide Cutterhead with eight 8-knife or 10-knife, 7″ cutting circle.

Cutterhead Motors:

- Top Cutterhead: 75 HP, 3600 RPM @ 60 Hz TEFC premium efficiency direct coupled motor.

- Bottom Cutterhead: 50 HP, 3600 RPM @ 60 Hz TEFC premium efficiency direct coupled motor.

Feed System:

- Three pneumatic tire top rolls approximately 16″ diameter with 1-1/2″ independent yield and three 14″ diameter steel bottom rolls.

- Top rolls are powered by two 15 hp helical gear motors with AC variable frequency drives.

Top Head Chipbreaker:

- Independently yielding 3″ wide sections. 1-1/2″ yield of each section.

- Air operated quick release of the chipbreaker is standard.

Optional Equipment:

- Automatic Cut Control TM

- Anti-lap device – watch video clip

- Pinch rolls

- Anti-kickback ringers

- Digital thickness positioning of top head

- Helical Carbide Cutterheads

- Remote console to extend planer controls to operator’s position

- Top head power hoist

- Air operated pressure bar release

- Hydraulic drive

You must be logged in to post a review.

Reviews

There are no reviews yet.