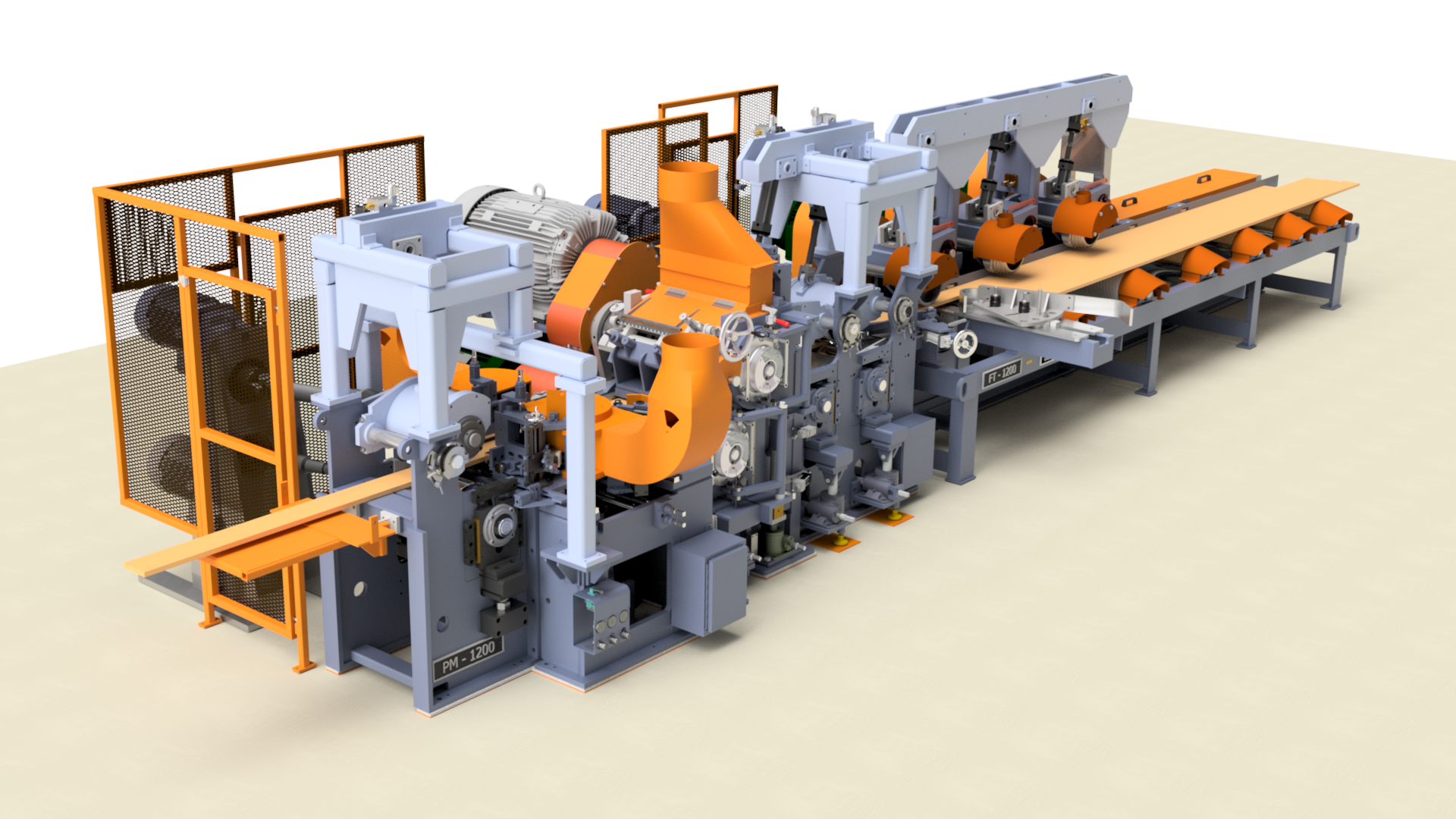

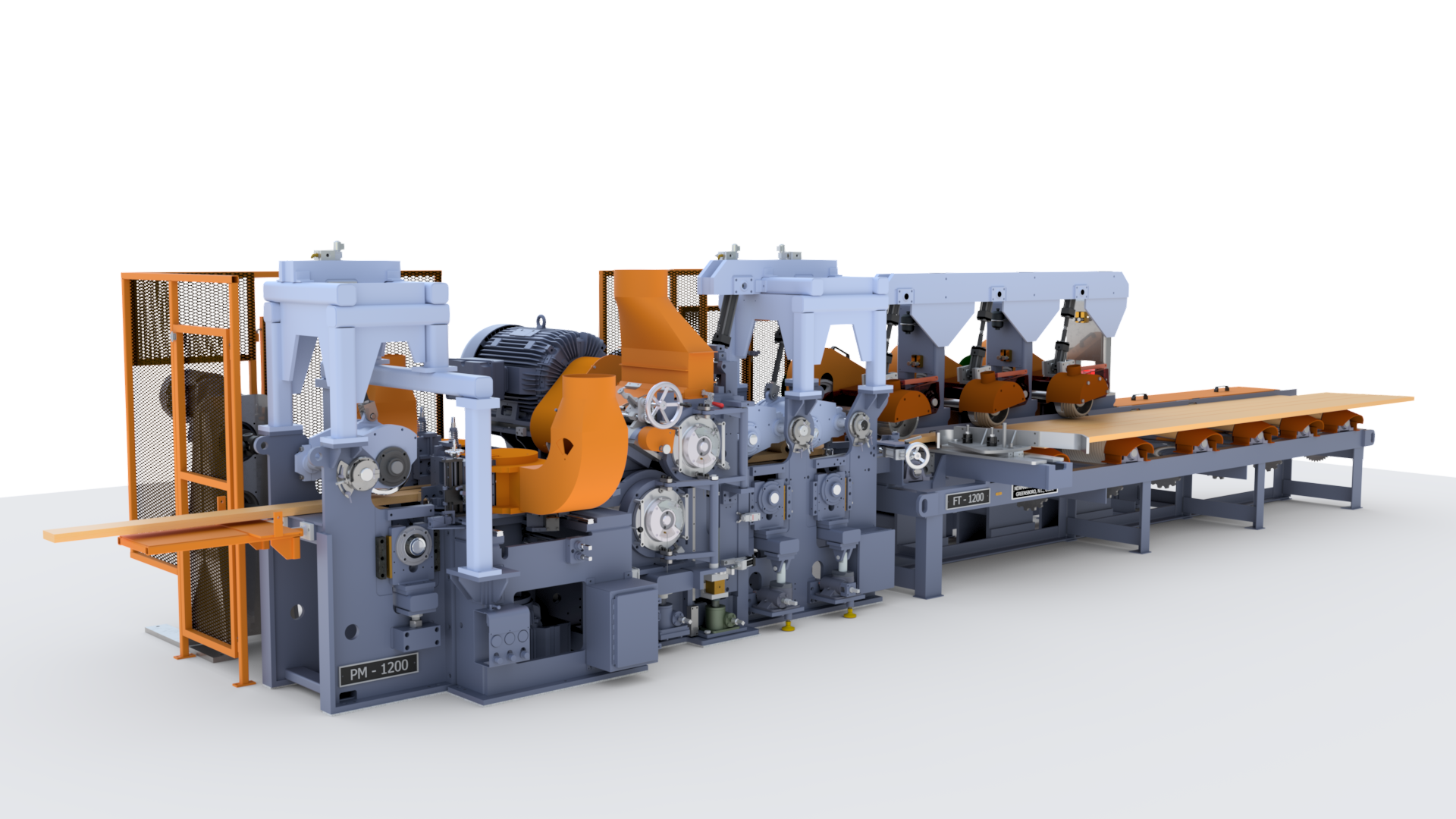

EPR-18 Double Roughing Planer

The Newman EPR Electric Series Double Roughing Planers provide state-of-the-art technology backed by the world's most experienced planer manufacturer. Newman's new EPR Series Planers feature electric feed drive. Additional innovative features include an improved locking mechanism for the cutterhead leveling system, and redesigned bottom cutterhead dust collection.

The benefits of the new, environmentally friendly EPR Series Planers include precision feed roll synchronization, extended tire life, superior feeding, precision grinding and jointing, new digital thickness indicator, and reduced maintenance.

Description

The Newman EPR Electric Series Double Roughing Planers provide state-of-the-art technology backed by the world’s most experienced planer manufacturer. Newman’s new EPR Series Planers feature electric feed drive. Additional innovative features include an improved locking mechanism for the cutterhead leveling system, and redesigned bottom cutterhead dust collection.

The benefits of the new, environmentally friendly EPR Series Planers include precision feed roll synchronization, extended tire life, superior feeding, precision grinding and jointing, new digital thickness indicator, and reduced maintenance.

The EPR Series Double Roughing Planers are designed specifically for surfacing rough lumber in board lengths. Planing in long lengths helps cut-off saw operators to see defects more accurately, therefore making better decisions, resulting in increased yield. The minimization of snipe and other machining defects also contributes to increased yield. Planing in long lengths provides maximum productivity at high feed speeds.

Newman Helical Carbide Cutterheads provide extended knife life and low maintenance at reduced noise levels. Our exclusive Automatic Cut Control™ (A.C.C.) is the answer to “scant” lumber planing as it is designed to prevent thin boards from being planed to less than target size. Combining these features on any EPR Series Planer guarantees maximum yield at the absolute minimum operating costs.

Capacities:

- Maximum Feed Opening: 18″ x 6″

- Mininum Stock Thickness: 3/8″

- Minimum Stock Length: 51″ (48″ when butted)

Feed Speed:

- Minimum Feed Speed: 40 FPM

- Maximum Feed Speed: 150 FPM

Cutterheads:

- 6-knife, high speed steel 7″ cutting circle

- Optional: Helical Carbide Cutterhead with 6-knife or 8-knife, 7″ cutting circle

Cutterhead Motors:

- Top Cutterhead: 40 HP, 3600 RPM @ 60 Hz TEFC premium efficiency direct coupled motor

- Bottom Cutterhead: 25 HP, 3600 RPM @ 60 Hz TEFC premium efficiency direct coupled motor

- Digital thickness indicator is standard.

Feed System:

- Top: Two 16″ pneumatic tire rolls with 1-1/2″ independent yield

- Bottom: Four 4″ diameter steel infeed rolls and one 12″ diameter steel outfeed roll

- Top rolls are powered by two 10 HP helical gear motors with AC variable frequency drive

Top Head Chipbreaker:

- Independently yielding 3″ wide sections. 1-1/2″ yield of each section.

- Air operated quick release of the chipbreaker is standard

Optional Equipment:

- Automatic Cut Control TM

- Anti-lap device – watch video clip

- Pinch rolls

- Anti-kickback fingers

- Digital thickness positioning of top head

- Helical Carbide Cutterheads

- Remote console to extend planer controls to operator’s position

- Top head power hoist

- Air operated pressure bar release

- Hydraulic drive

You must be logged in to post a review.

Reviews

There are no reviews yet.