G-716A Fully Automatic Cutterhead Grinder

Video for G-716a – Fully Automatic Cutterhead Grinder

Newman G-716a Cutterhead Grinder is designed for face grinding cutterheads with either steel or carbide cutters. It will grind either Eased Edge or Milled to Pattern cutter heads with a Cutting Circles of between 7” to 16”, up to 12″ in length. It has Automatic table traversing, Automatic knife row indexing and Automatic infeed. The G-716a is furnished with a coolant system, three tier sediment tray, 20-gallon tank and a wash down hose.

Description

Video for G-716a – Fully Automatic Cutterhead Grinder

Newman G-716a Cutterhead Grinder is designed for face grinding cutterheads with either steel or carbide cutters. It will grind either Eased Edge or Milled to Pattern cutter heads with a Cutting Circles of between 7” to 16”, up to 12″ in length. It has Automatic table traversing, Automatic knife row indexing and Automatic infeed. The G-716a is furnished with a coolant system, three tier sediment tray, 20-gallon tank and a wash down hose.

The G-716a Has no Index Plate to Change

No index plate to change when working with heads with different numbers of knives. The use of an index plate assumes that the knives and head separations are uniform throughout, which is often not the case. If the height of the knife is high or low, then the front face of the knife will vary from knife to knife making the task of grinding difficult. The Newman G-716a Fully Automatic Cutterhead Grinder now employs a Servo motor robotic gearbox that eliminates the need for a positive stop while providing accurate indexing regardless of the irregularities in the knives and head slots.

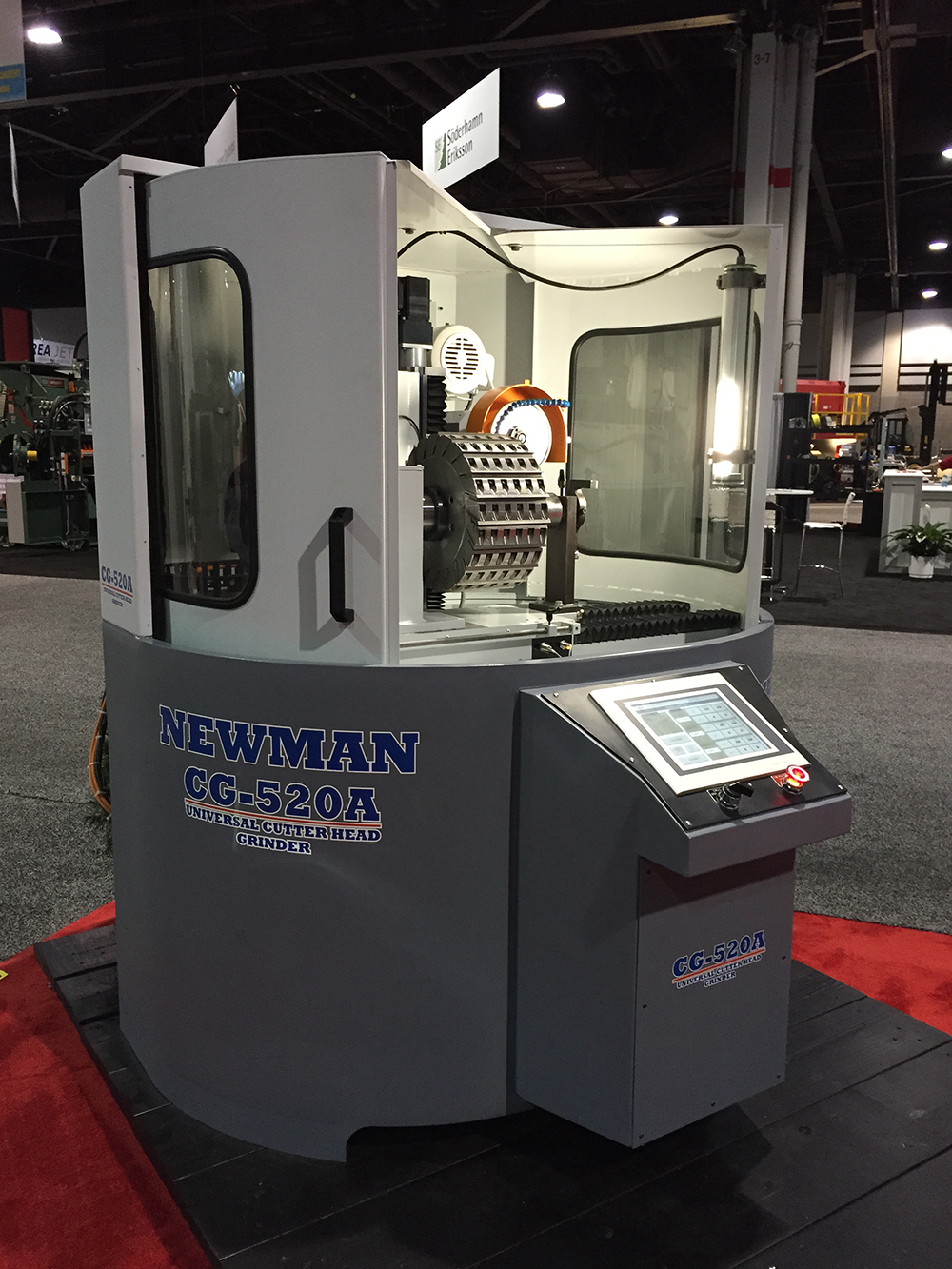

Completely Enclosed Grinding Area

Completely enclosed grinding area provides for a safer and cleaner grinding room. The work area is completely enclosed by a new wrap around two-part hood mounted on track bearings. The closed hood provides a tight seal with the coolant recovery tray. Coolant and grinding debris are carried away by the flooded coolant system and returned to the coolant reservoir. Since all the grinding debris and coolant are completely contained within the grinding hood there is no need for a pneumatic airborne particulate collection system.

Touch Screen Operator Panel

A high contrast LCD display operator interface provides a user-friendly system for programming the parameters specific to the cutterhead to be ground. The display keeps the operator informed of the current status by displaying cycles completed and total grind.

Head Indexing and Wheel Feed:

- Programmable / Automatic

Minimum / Maximum Diameter Cutterhead:

- 7″ Min./16″Max.

Worktable Feed:

- Air / Oil

Travel (maximum):

- 12″

Adjustable Limits:

- Proximity Switch

Speed:

- Fully Adjustable

Index Method:

- Programmable Number of Knives

- Servo Motor Index against a Positive Stop

- Automatic Brake Lock / Unlock

Grinding Spindle:

- 1-1/2 HP Wash Down Duty TEFC Motor

- 3600 RPM, 230/460VAC 3PH

- 575VAC 3PH Dual ABEC 7 Precision Bearingsl with Sealed Lubrication

- 8″ Diameter Grinding Wheel (9″ Diameter Max.)

Coolant System:

- 15 Gallon Tank with Casters, Sediment Tray

- Full View Sight Glass

- 5 GPM Pump (120VAC) Wash Down Hose Included

Specifications:

- Grinds 7″ to 16″ diameter eased edge, milled to pattern, and finger joint heads

- Automatic traversing worktable with adjustable travel limits

- Automatic indexing of knives against a positive stop with grinding position pneumatic brake allowing precision indexing without the need of an index plate

- High precision 1-1/2 HP grinding spindle with sealed lubrication

- Recirculating adjustable flow flooded coolant system with wash down hose

- Fully enclosed grinding chamber with viewing windows and task light

- Grinding wheel feed provides unattended operation

- Color touch screen operator interface

Reviews

There are no reviews yet.