PM-1600 High Speed Planer Matcher

Video for PM-1600

Video #2 for PM-1600

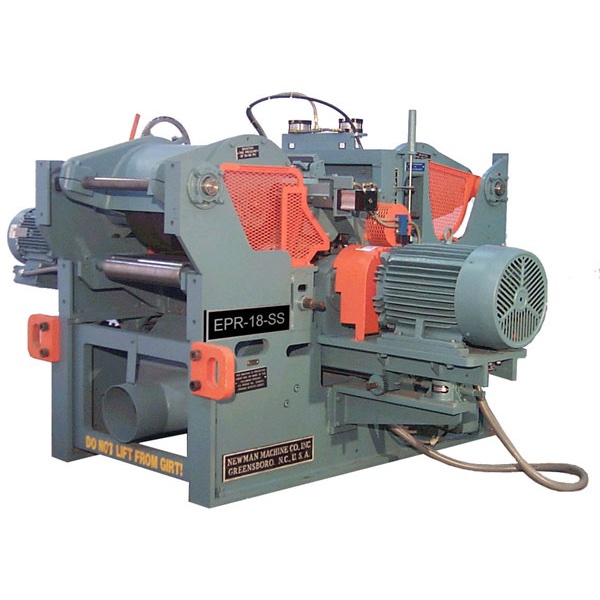

Newman has developed the PM-1600 modular, high-speed, four-sided planer to produce a high quality finish on lumber ranging in size from 1″ x 3″ to 6″x 15″.

An electrically driven planer with computer controlled roll speed synchronization, cutterhead positioning, optimized speed control and touch screen operator interface, the PM-1600 comes standard with Quick Change Head (QCH) modular assembly, allowing for a variety of tooling. It is capable of feed speeds up to 3,000 fpm. The PM-1600 is available with an inboard or outboard profiler, an additional mid-roll to make it an eight-roll machine and a high quality finish module to make it a six-head model.

Description

Newman has developed the PM-1600 modular, high-speed, four-sided planer to produce a high quality finish on lumber ranging in size from 1″ x 3″ to 6″x 15″.

An electrically driven planer with computer controlled roll speed synchronization, cutterhead positioning, optimized speed control and touch screen operator interface, the PM-1600 comes standard with Quick Change Head (QCH) modular assembly, allowing for a variety of tooling. It is capable of feed speeds up to 3,000 fpm. The PM-1600 is available with an inboard or outboard profiler, an additional mid-roll to make it an eight-roll machine and a high quality finish module to make it a six-head model.

The heavy-duty four-sided planer matcher with 16″ diameter steel feed rolls, is built to last in a demanding environment, without sacrificing production or quality. Newman has led the industry with innovations such as the Newman Helical Carbide Cutterheads, quick-change cutterheads, computer diagnostics, electric and/or pneumatic feed works and fabricated steel frames.

- Electric or Hydraulic drive with feed speeds up to 3000 fpm

- Quick Change Hydraulic locking cutterheads standard with 3-1/4” diameter spindles for all heads

- Full dimension planer with a capacity of 15” x 6”

- Heavy duty 1-1/2” thick steel plate frame members

- All weldments are oven stress relieved prior to machining

- 16” diameter reversible feed rolls

- Hydraulic positioning and tensioning of feed rolls with encoder feedback for quick open and reset

- Absolute encoder feedback for top head and side head set works

- TEFC cutterhead motors are standard

- Quick-set simultaneous bottom roll setting

- Up to 200 HP on top head, 150 HP on bottom head and 75 HP on side heads

Reviews

There are no reviews yet.